|

Ari Holopainen / build | |

| BUILDING TIPS Here is some building tips that are useful to know when you design or build complex lego gearboxes. Some of the tips are for lego designing only but some of them are universal for all kind of gearbox designing. In complex lego gearbox you can’t always get optimized structure but with these building tips you can make better compromises. You can click pictures to enlarge them. Use only two support points per axle: Universal

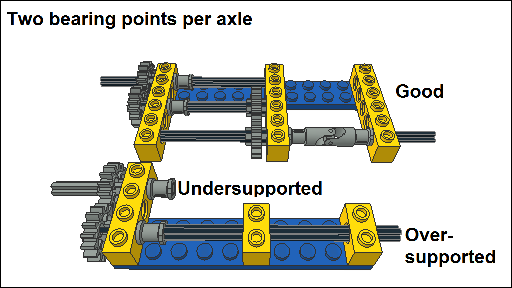

When you support axle with bricks with holes use only 2 support (bearing) points. 1 support point is not enough so axle will tilt too much under load. 3 stud long axle is an exception, also idler gears need only 1 support point. When you use 3 support points axle will be oversupported so avoid it. If axle is bent or support points are not exactly coaxial in oversupport situation axle won’t rotate smoothly and you will have too much losses. Also connecting 2 axles together with axle joiner can mean that connected axles are not straight structure. If multiple axle structure is very long and more than 2 support points are needed use universal joint so axle won’t be oversupported. Worm gear has loose contact with axles so it can be used instead of universal joint if it has in full length axlehole inside it. Locate gear wheels near to support points: Universal

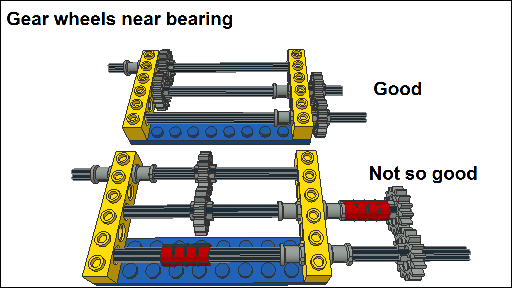

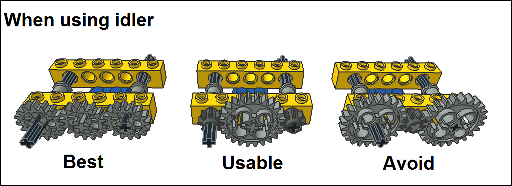

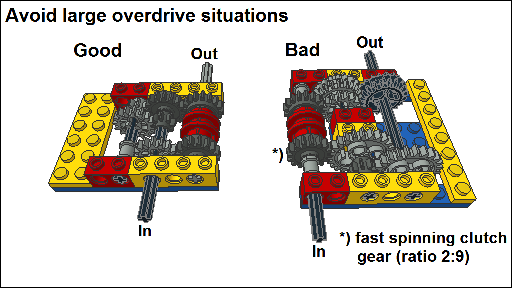

Gear wheels that transmit high torque should be located near to support (bearing) points. There are 2 reasons for that. If axle is bent gear wheel that is far from support point will be alternately close and far from its pair gear wheel during rotation. Being too close will reduce efficiency and too far can mean contact loss. Also high torque bends temporarely axles so gear pair can lose mesh if it is far from support point. If you need to connect long axles together some of the gear pairs can be too far from bearing points and structure won’t work. In that case add more support points and use universal joint between axles. Note that this concerns not only gear wheels between support points but also gear wheels at the end of axle. If axle comes only 1 or 2 studs out from support point structure is very good. 3 studs out from support point is usable but 4 studs needs tests to know does it work. I have used structure where last gear wheel at the end of axle is 4 studs from support point but this axle has high rotating speed so it’s not under high torque. Avoid large overdrive situations: Lego issue Overdrive means that output rotates faster than input. In axles and gear pairs works equation power = torque x rotating speed so the lower speed the higher torque and vice versa. Only motor produces power so power won’t appear or disappear in drive line except some losses due to friction. Every support point (lego brick) has some friction and in high rotating axles larger portion of torque can be lost. With high rotating motor you can’t avoid high speeds but you can avoid situations where speed is first increased and then decreased. For example large idler gear and small gear wheels around it is better than small idler gear between large gears. I’m not sure why but in lego world overdrive gear pair seems to have worse efficiency than same gear pair in underdrive situation.

Both lego synchro gearboxes and sequential sliding axle gearboxes should be designed so that there are no large speed increases in any parts in any gear. For example in lego synchro range-change unit (high gear step) is important to locate synchro parts (transmission driving ring) into output axle. This way low range’s synchro gear (16 teeth with clutch) will rotate slow when high range is connected. If synchro parts are in input axle synchro gear of low range will rotate much faster than input when you have high range connected. And this can mean high losses. So sometimes you have to think reversed from output axle through constant gear pairs to synchro parts to see if there are too large overdrive situations in certain gearbox.

One thing you easily forget is reverse gear and what it can mean to efficiency. When you have reverse gear in your transmission 16 teeth clutch gear rotates in different direction than its axle. It’s same situation as clutch gear rotating fast on stopped axle. When you drive forward only reverse gear’s clutch gear rotates to opposite direction but in reverse gear many clutch gears rotate in different direction than their axles and this can mean losses. Usually reverse gear is slow so possible efficiency problem is not big but if you have efficiency problems in your transmission removing reverse gear can help. While lego motors run in both directions you don’t necessary need reverse gears in lego transmissions. Prefer high gears and their efficiency: Universal Again remember equation power = torque x rotating speed. Torque is that what moves your vehicle and power tells how fast you can go with that torque. So, the higher speed the more power you need to get same torque to driven wheels. That’s why it is advisable to prefer high gears and concentrate to optimize their efficiency. In practise you design lego gearbox so that power flow through gearbox is simpler in high gears than in lower gears. For example you can design 6-speed gearbox so that in top gear power goes through 1 gear pair, in middle gears through 3 gear pairs while 1st and 2nd gear need 5 gear pairs. Normally the less gear pairs in certain gear the better efficiency you have in that gear. Also the smaller ratio change the better efficiency certain gear has. So direct top gear gives better efficiency than overdrive top gear. Heavy loaded in steep hill asks also power but you can always choose lower gear (higher ratio) and go slower to get enough torque. That’s why it’s acceptable that lower gears have worse efficiency than higher gears. If you don’t get enough torque with 1st gear you need larger overall gear ratio to get higher ratio for 1st gear (overall gear ratio = ratio 1st gear / ratio top gear). In lego world overall gear ratio 15 or more usually gives enough torque for 1st gear even in heavy truck use. This means that 1st gear gives 15x torque and 1/15 of speed compared to top gear. When total ratio of top gear is chosen so that vehicle gets enough torque to move smoothly in top gear 15x that torque is quite a lot and 1/15 of that speed is very slow. For example you get overall gear ratio 15 with basic 6-speed transmission that uses 8-24 gear pairs before synchro parts and 12-20 gear pair after them. Match engine and transmission: Universal Motor vehicle’s drive line is everything that transfers torque from motor to driven wheels. Typical drive line considers motor, clutch, multi-speed gearbox(es) and final drive. Combustion engine needs clutch to cut torque for shifting and stopping but in lego vehicles clutch is not needed. Multi-speed gearboxes mean main gearbox, splitter, range-change unit or other shiftable gearboxes. Final drive is usually speed reduction in differential and additional planetary hubs. In lego designs “final drive” means all single speed gear pairs outside shiftable gearboxes. Matching engine and transmission is three things: total ratio of top gear, total ratio of 1st gear and number of gears. Final drive ratio should be chosen so that vehicle has enough power to go on smoothly with top gear in highest speed limit. While economy is very important nowadays engine rpm should be in economical zone (if possible) also in highest designed driving speed. While lego motors are usually constant speed designs total ratio should be chosen so that in top gear lego vehicle goes on smoothly (no significant motor rpm drop) on easy flat terrain but still as fast as possible. If lego motor’s rpm drops too much you need higher total ratio (lower top speed) but if vehicle still goes on smoothly with top gear even on rougher terrain you can test lower total ratio (higher top speed). Second matching issue is total ratio of 1st gear, this means equation overall gear ratio = ratio 1st gear / ratio top gear. Slow 1st gear is needed for startability and gradeability. Vehicle must be capable to move off in difficult conditions and to climb steep hills even in heavy loaded. In lego vehicle ratio of 1st gear is for gradeability and rough terrains heavy loaded. Personal car can “survive” with overall gear ratios 4,00-4,50 but heavy duty trucks need as high values as 15-20. In some tractors and severe duty trucks extra low speeds are needed so desired crawling speed can increase total ratio of 1st gear and overall gear ratio. When you know overall gear ratio (total ratios of 1st gear and top gear) you need to choose total number of gears. This means question how large gear steps are acceptable. The smaller gear steps and larger overall gear ratio the more gears you will need. Typical steps between two sequential gears start from 1,17 but even larges steps stay under 2,00 due to limits of combustion engine. In trucks and personal cars the most important is gear step between two top gears. If you need only main gearbox (max 7 speeds in manual transmission) progressive gear steps help to increase overall gear ratio. Progressive gear steps mean the higher gear the smaller step between gears. If you need also splitter and/or range-change unit gear steps will be geometrical or only partly progressive. All in all, in linehaul truck gear steps and overall gear ratio of 10-speed transmission can be acceptable and you don’t need heavy duty 18-speed transmission. Too many gears usually means more gear skipping in shifting procedure and slightly worse efficiency. In 8- and 9-speed transmissions top step 7-8 (and 3-4 due to range-change unit) is usually smaller than other steps. This gives better performance in high speeds without losing high overall gear ratio so you don’t need so many gears. Be careful with high ratios: Lego issue Again we need equation overall gear ratio = ratio 1st gear / ratio top gear. Here we expect that ratio of top gear is chosen so that lego vehicle goes as fast as it can and gets enough torque to move smoothly with top gear. If motor is capable to give more speed to the vehicle than present ratio of top gear allows things said next are even more important. When you have gearbox with large overall gear ratio (>15) you have to be careful with lower gears. Lego motors are not very powerful but 15x or more their torque is a lot for lego parts. Remember that final drive (rest of the speed reduction) in drive line also multiply torque. Most critical parts of drive line are near to driven wheels, for example inner gear wheels of differential. If you choose very slow gear, put weight on your lego vehicle to prevent wheel slip and drive against wall something will break before motor stalls. Usually it’s 8 teeth gear or 12 and 14 teeth bevel gears but I have broken also 24 teeth spur gear so be careful with high ratios. In real world’s gearboxes the higher ratio and torque the more width you need in gear wheels. That is why splitter and main gearbox are always before range-change unit so they don’t have to transmit high torque made by low range. But in legos you have only one width. If you have broken inner gear wheels of differential it’s good to use hub reduction (gear pairs between differential and wheels). For example gear pair 8-24 drops torque to 1/3 in differential but then 8 teeth gears are the most critical parts. But if you use parallel two 8-24 gear pairs per wheel you double the width of the gear pair. But anyway, give mercy to your lego vehicle and use slow gears because of their slow speeds not because of their high torque. :-) Limit the number of synchro gearboxes: Lego issue There is a lot of backlash between transmission driving ring and 16 teeth clutch gear (synchro parts) when they are connected. This is to ensure smooth gear connection in every situations. But it means bad reaction time in drive line when you change driving direction or when traction changes to engine braking or vice versa. In some situations backlash in drive line can lead to jerking motion so that traction and engine braking alternate all the time. That is why it’s advisable to limit the number of synchro gearboxes in drive line because all of them need connected transmission driving ring. Note that main gearbox can have as much as four transmission driving rings without a problem while only one of them is active at a time. I have limited number of active transmission driving rings and synchro gearboxes to two in one drive line because three will cause so much backlash. This means that in transmission with main gearbox, splitter and range-change unit at least one auxiliary gearbox has to be sliding axle construction. You can minimize backlash problem by putting synchro gearboxes with transmission driving rings right next to motor and sliding axle gearboxes and the rest of the speed reduction after them. Transmission driving ring extension doubles the backlash so it’s good to avoid it. In some situations you can use two 16 teeth clutch gears connected together on their dog clutch side. But if you have to use transmission driving ring extension try to use it before underdrive gear pairs and avoid before direct or overdrive gear pairs. But remember that too large speed reduction in same gearbox after transmission driving ring causes fast rotating 16 teeth clutch gears when other gears are connected. And that means poorer efficiency in lego world. So sometimes you have to make compromises between efficiency and backlash problems. Prefer double bevel type gears in sliding axle gearboxes: Lego issue As told before I use at least one sliding axle (sequential) gearbox if transmission has main gearbox, splitter and range-change unit. This is to minimize backlash problem made by synchro parts (transmission driving rings and 16 teeth clutch gears). I usually use 2-stage structure with three axles: input axle, sliding axle and output axle. But sliding axle gearboxes can have gear connecting problems when there are gear pairs done by spur gears. If you have difficulties to connect a gear you can drive motor very shortly during shifting to get teeth of gear wheels in new positions. Old 8 and 16 teeth gear wheels are problematical but 24 teeth spur gear can be replaced with 24 teeth crown gear. New 12, 20 and 28 teeth gear wheels are double bevel type so they are easier to connect. (I don’t use 36 or 40 teeth gear wheels in my gearboxes while they are so large. Self-made differentials is a different story.) So, sliding axle gearbox has easier gear connects when all gear pairs have at least one double bevel type gear wheel (or crown gear). This means avoiding 8-16 and 16-16 gear pairs. Most problematic to connect is gear that has only spur gear gear pairs like two 8-16:s or 16-16-16. For example range-change unit’s gear step 4,00 can be done with two 12-24 gear pairs instead of two 8-16:s. You get this gear step also with underdrive solution by using 8-24 and 12-24 gear pairs in low range (ratio 6,00) and 8-24-12 gear pairs in high range (ratio 1,50). You can’t always avoid spur gear gear pairs in sliding axle gearboxes but it’s worth checking if you can get same gear step by using different gear pairs. Avoid rubber belt drive: Lego issue In some cases axles can have such locations that it’s impossible to use lego gear pair. Then the only solution is rubber belt drive. But always try to avoid rubber belt drive. Rubber belt needs tension to be able transmit torque without slipping. But used tension also tries to move axles closer to each other and only support bricks prevent that movement. This leads to radial forces between axles and support bricks which means more friction and poorer efficiency. If you don’t have other solution available than rubber belt drive test with different rubber belts the lowest possible tension that doesn’t cause slipping in the hardest driving situation. This way you can minimize losses and get better efficiency. [Back to main page] |

|

Primary content in this document is © Ari Holopainen. All other text, images, or trademarks in this document are the intellectual property of their respective owners. |

| |

©2005 LUGNET. All rights reserved. - hosted by steinbruch.info GbR |